Gas Taps in a Laboratory

Gas taps in a laboratory are fixtures designed to control the flow of gas, typically used for experiments (the simple Bunsen burner especially in schools!) and other laboratory processes. These gas taps are an essential component of any laboratory infrastructure, allowing researchers and technicians to regulate the supply of gases such as natural gas, hydrogen, nitrogen, oxygen, or other specialised gases required for experiments.

Here are some key features and considerations regarding gas taps in a laboratory:

- Types of Gas Taps: There are various types of gas taps, including:

- Needle valve taps: These taps provide precise control over the flow rate of gas.

- Drop lever gas taps: These taps have a drop lever mechanism for opening and closing the valve. Great in schools, where the teacher can quickly and easily identify if they have been left in the ‘on’ position.

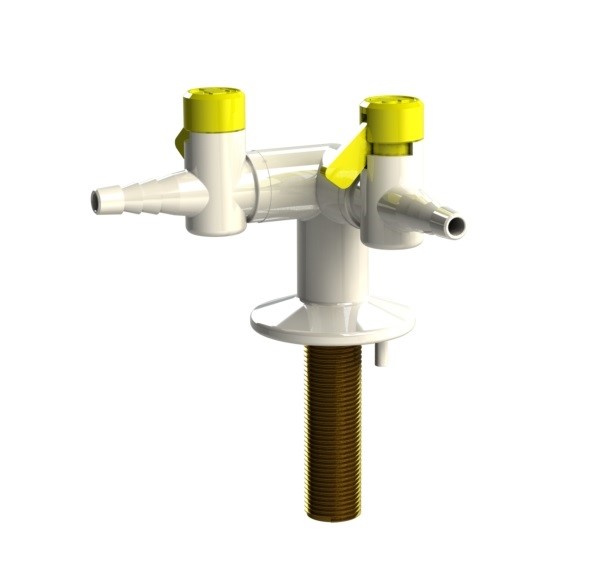

- Multi-outlet taps: These taps allow multiple gas lines to be connected and controlled individually.

- Safety: Safety is paramount when working with gases in a laboratory. Gas taps should be designed with safety features such as:

- Secure shut-off mechanisms to prevent gas leaks.

- Labels indicating the type of gas and appropriate usage (see our post on DIN EN 13792).

- Color-coding for easy identification of different gases.

- Emergency shut-off valves in case of leaks or other hazards.

- Compatibility: Gas taps should be compatible with the types of gases used in the laboratory. Different gases may require different materials for the taps to prevent corrosion or contamination.

- Installation and Maintenance: Proper installation and regular maintenance are crucial for the safe and efficient operation of gas taps. Maintenance may include:

- Periodic inspection for leaks or damage.

- Lubrication of moving parts to ensure smooth operation.

- Replacement of worn-out components as needed.

- Location and Accessibility: Gas taps should be strategically located for easy access and operation. They should be positioned away from sources of heat or ignition to reduce the risk of accidents.

- Regulations and Standards: Gas taps should comply with relevant safety regulations and standards, such as those set by regulatory agencies or industry organisations. All our gas taps come with BSI British Gas certification and a 5 year warranty.

- Training: Laboratory personnel should receive proper training on the safe use of gas taps, including procedures for turning them on and off, handling leaks, and emergency protocols.

Overall, gas taps play a crucial role in laboratory operations, and their proper design, installation, and maintenance are essential for ensuring safety and efficiency in gas handling procedures.

A school laboratory showing gas and water taps